Automotive &

mobility

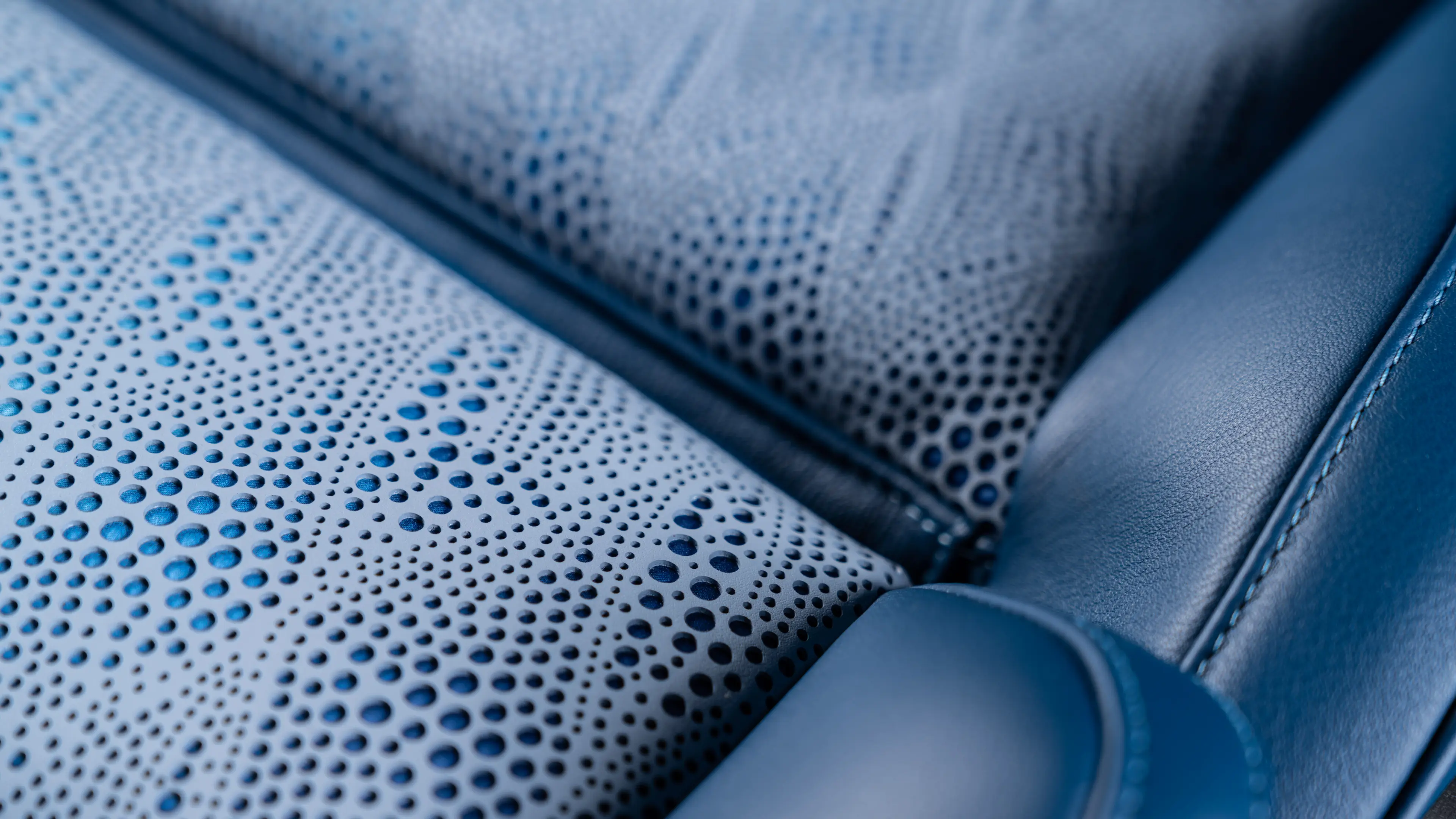

Endowed with decades of craftsmanship and industry insight, Rino Mastrotto excels in serving the premium and luxury automotive industry. We harness the essence of our heritage while simultaneously incorporating modern innovation to produce authentic superior leather for high-end vehicles. Our Swedish company, Elmo, and our Italian brand Brusarosco bolster our automotive expertise with their industry-leading capabilities. Sustainability remains central to our manufacturing process, as we firmly believe that premium automotive experiences and environmental consciousness should go hand in hand. Our unique ability to facilitate synergies and deliver bespoke services to our clientele reflects our commitment to setting new industry standards and affirming our strategic role in the automotive and mobility sector. We proudly cater to diverse domains, including cars, aviation, marine, commercial vehicles, and mobility solutions by providing comfort and performance for luxury in motion.

Our customer journey

Capabilities

Europe

- Full-cycle leather tanneries from raw hides to cut parts

- Scandinavian & European rawhides predominantly

- Solutions for all interior applications including seating, SW, IP, CC, DP etc.

- Cutting plant equipped with digital marking, CNC cutting, lamination, splitting, sharpening operations, perforation, and clustering machines

- Multiple embossing options

- Luxury aniline and semi-aniline value propositions

- In-house R&D Automotive leather centre for customised projects with a quick turnaround time

- In-house design & trend capabilities

- In-house labs for testing of both customer-specific and generic technical specifications

- Itinerant international automotive leather design show

- Custom colour development

- Stock of 300 colours for concept vehicles and serial production

- Customer-oriented technical support and customer quality assurance from new developments to serial mass production

- Sustainable bio-based tanning technologies and products

- Sustainable lightweight leather value propositions

- 100% renewable on energy at Elmo and 100% renewable on electricity at Brusarosco

- Sustainable and industry-leading ‘Zero Waste Leather’ concept

- 100% circular manufacturing & 0% process waste to landfill

- Animal welfare 6 freedoms and ICEC-certified traceability back to farm with ‘Excellent’ rating

- Ethical claim certification “We recover our hides from the food chain”, issued by ICEC

- Excelling, and an industry benchmark, in air emission reduction (VOC)

- LCA cradle-to-gate (core and upstream) on product and process level verified by DNV

Americas

- Automotive industry mindset and cutting-edge technologies

- Solutions for all interior applications including seating, SW, IP, CC, DP etc.

- Evolved management system fully integrated with production planning & traceability system

- Finishing and cutting plant equipped with automatic cutting technology, lamination, sharpening and perforation machines at Brusarosco de México

- Wet blue, crust, finishing and cutting plant equipped with roller press technology with RFID nesting system, lamination and perforation machines, and decorative sewing at Bermas in Brazil

- Customer-oriented technical support and customer quality assurance from new developments to serial mass production

- Itinerant international automotive leather design show

- Custom colour development

- Design & trend capabilities

- Strategic location to supply the North American market from a dedicated leather district at Brusarosco de México

- Strategic location for logistics and sourcing hides in South America at Bermas

- High production capacity with available potential expansion at Brusarosco de México

- In-house labs for testing of both customer specific and generic technical specifications

- 100% electric energy from renewable sources at Bermas

- High-efficiency internal water treatment plant at Bermas

Rooted in a rich history dating back to 1834, Brusarosco not only stands as the oldest operating tannery brand in Italy but also symbolises an enduring legacy of leather craftsmanship. Renowned for producing exquisite, innovative, and sustainable leather primarily for the automotive industry - seats, steering wheels, instrument and door panels - it operates one of Europe's largest production facilities. Through vertical integration, Brusarosco has incorporated all phases of the tanning and cutting process, to maintain rigorous quality standards, exercise greater flexibility, and streamline efficiency.

Brusarosco embraces a 100% circular manufacturing methodology, championing the unique concept of 'Zero Waste Leather.' By implementing state-of-the-art technology and pioneering processes, it eliminates solid waste production, ensuring that every by-product is upcycled efficiently and responsibly. In 2021, Brusarosco received the ICEC certification of traceability back to the farm with an ‘Excellent’ rating up to the place(s) of breeding. The following year, it was also awarded LWG Gold certification.

Established in 1931, Elmo is acclaimed for its production of high-quality leather by specialising in aniline and semi-aniline leather propositions, catering primarily to the automotive and furniture sectors across more than 40 global markets. It is renowned for its state-of-the-art research and development department, dedicated to the continuous development of innovative products, and for its in-house laboratory which ensures rigorous testing and the maintenance of impeccable product quality control. Furthermore, its inventory of readily available products is unrivalled and constitutes a benchmark in the market for both the interior design and automotive segments.

Operating from its base in Svenljunga, Sweden, Elmo has been at the forefront of sustainability in the industry since the 1980s, driving the industry by switching from solvent-based coatings to water-based coatings and excelling in air emission reduction. Elmo has also introduced a fully circular manufacturing process that eliminates all process waste through upcycling, recycling, and energy recovery. This approach has led to the introduction of the pioneering and industry-leading 'Zero Waste Leather' concept, marking a notable innovation in sustainable production practices. With an ‘Excellent’ rating up to the place(s) of breeding, Elmo also achieved ICEC certification of traceability back to the farm in 2023. Additionally, it responsibly sources surface water from a nearby river, purifies it through a highly efficient biological plant and returns it to its source in an equal or improved condition. Downstream, a regional cleaning facility further filters the water, supplying cities on the Swedish West Coast with clean drinking water.