Luxury

creations

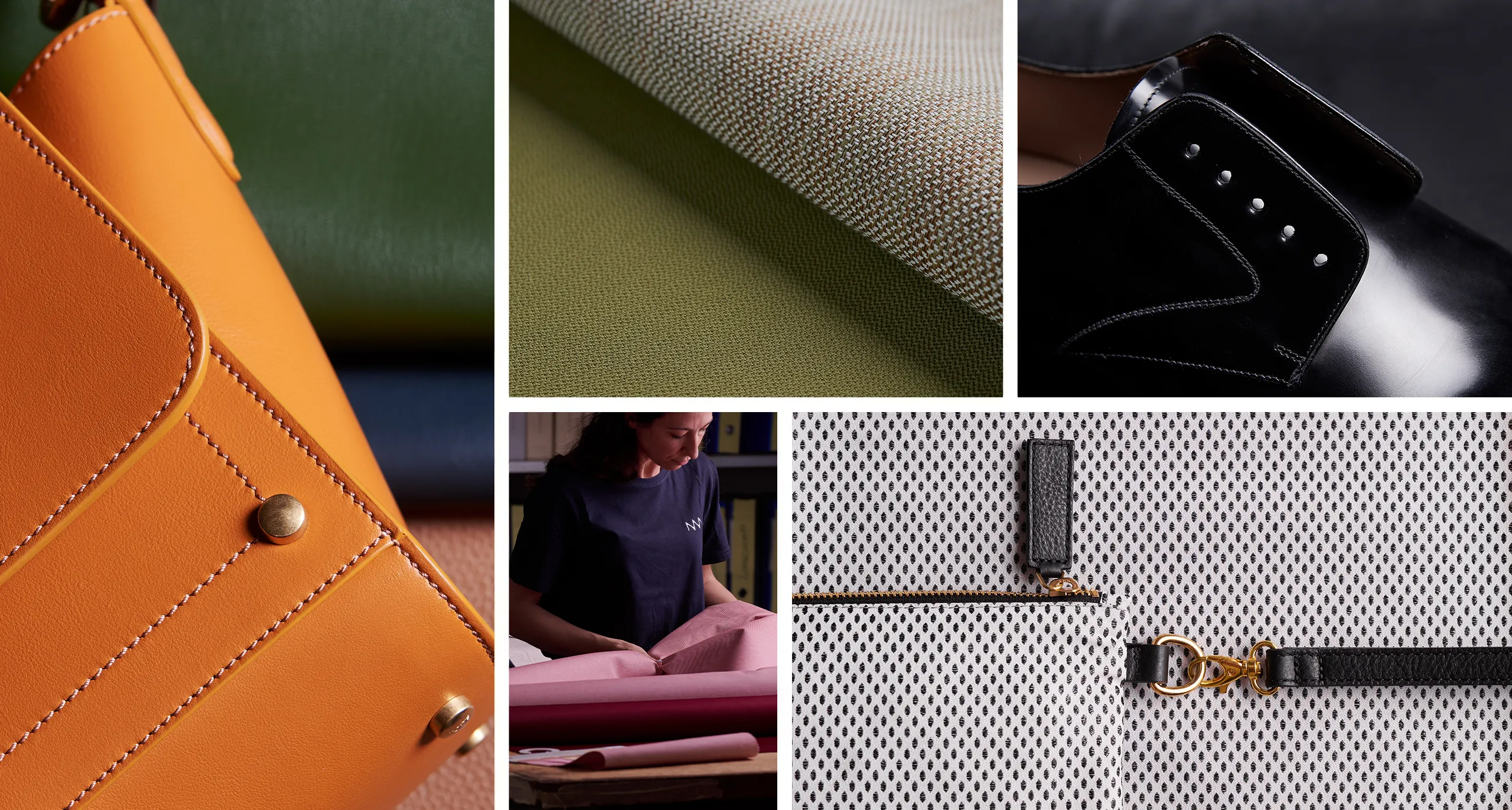

Leveraging its rich Italian savoir-faire, Rino Mastrotto specialises in serving the luxury fashion industry. Our expertise extends from producing the finest leather—carefully transformed from raw hides to finished material—to encompass high-end textiles and bespoke services that align with our clients' visions. With sustainability at the heart of our manufacturing ethos, we believe that luxury and eco-consciousness are intertwined. Our unique capacity to create synergies ensures an unmatched consolidation of services, setting new industry benchmarks and providing strategic value to our clientele.

Our customer journey

Capabilities

Leather

- Full cycle leather tanneries from raw hides to finished leather

- Specialised in the production of top-of-the-range bovine, calf, and suede for luxury leather goods and footwear

- Customised embossed leather

- Flexible production processes, swift response time, precise and prompt communication

- Trend scouting and ‘ready-to-use’ project development

- In-house state-of-the-art R&D departments available for customised projects

- In-house laboratory for physical and mechanical tests

- New showroom designed as an exhibition centre with permanent collections of all the luxury division’s tanneries

- Leather product footprint made by LCA assessment

- Raw hides from selected suppliers mainly from Europe

- Back to farm certified traceability and Ethical claim certification “We recover our hides from the food chain”, issued by ICEC, at Basmar

- LWG-certified tanneries

- Bio-based chemicals, water-based finishing

- Chemical management by following ZDHC guidelines

- 100% renewable on electricity supplied by the grid

- Internal wastewater treatment plants

Textile

- Full textile production control, flexibility, and fast delivery for customer satisfaction

- Customer-oriented and extensive R&D capability

- Weaving plant for jacquard and plain fabrics, internal dyeing, printing, and finishing

- Focus on sustainable fibres and traceability

- GOTS-certified Organic fabrics

- GRS-certified Recycled fabrics

- Better Cotton Supplier and Manufacturer member

- 100% renewable on electricity, partially sourced from our own 500 kWh solar panel plant

- ZDHC-approved chemical management

Basmar is the largest and most important production site dedicated to the production of exquisite leather for luxury leather goods and footwear. Founded in 1969, it operates an extensive, end-to-end process, from the receipt of primarily European raw hides to the creation of finished materials. Its ongoing collaboration with stakeholders in the luxury sector guarantees regular communication with the style departments of all customers, facilitating the development of 'ready-to-use' projects. Its R&D department collaborates closely with customers to propose innovative and alternative solutions, consistently meeting the stringent technical standards required. The tannery, having achieved the 'Progressive' level in the ZDHC Supplier to Zero programme, also operates its own wastewater treatment plant. This facilitates a significant production flexibility which generates increased customer satisfaction.

Basmar - Request information

Pomari has established itself as a partner of choice for top-tier luxury brands worldwide. As a frontrunner in the field of leather goods, Pomari continually seeks to innovate and elevate its production techniques. Specialising in meticulously curated, small to medium-sized calf skins from sought-after animals bred in Switzerland and France, Pomari has achieved an exceptional level of quality that meets the requests of the most demanding high-end clients and counts only the most exclusive luxury houses among its customers. This dedication allows Pomari to demonstrate its mastery over diverse materials, intuitively anticipate stylistic trends, and bring to life the most ambitious visions of luxury fashion. Pomari also owns its own wastewater treatment plant.

Pomari - Request information

As a specialised division within the group, Galassia is exclusively dedicated to the production of suede splits, used in both footwear sectors and leather goods. From luxury to casual and sportswear applications, Galassia's high-quality suede offerings cater to an extensive range of style preferences and functional demands.

Galassia - Request information

With its subsidiaries Mapel Textile and Mapel Components, Mapel Group is a major player in the supply of products and services dedicated to high fashion and luxury goods. A leader in the manufacture and distribution of ribbons, inserts and accessories, including handles, buckles, supports and profiles, Mapel Group offers customised solutions and services, from the design phase to the realisation of the finished product, serving over 300 customers in the fashion & luxury sector and employing over 80 people in its plants in Galliate Lombardo (VA) and Castellalto (TE). With over 30 years of experience, it joins Rino Mastrotto at the end of 2023.

Mapel Group - Request information

Building on the heritage of a historic tannery in the Tuscan tanning district, Nuova Osba specialises in crafting premium calfskins, predominantly for the high-end footwear sector but also for leather goods. By procuring raw materials from carefully selected suppliers and employing a slow pickling process for tanning, Nuova Osba can produce leather with distinctive characteristics and exquisite finishes, while preserving the natural qualities of the material to enhance its beauty and fragrance. With a reach spanning major markets globally, it combines time-honoured artisanal techniques with the latest technology to ensure uncompromising product quality, securing its position as a market leader and delivering uniquely valuable leathers that flawlessly blend classic style with modern fashion sensibilities.

Nuova Osba - Visit website

The recent acquisition of Tessitura Oreste Mariani, a distinguished company founded in 1937, marks a significant milestone in the group's growth. With its expertise in the creation of fabrics designed for use in finished products - mainly bags, shoes and ready-to-wear articles - Tessitura Oreste Mariani elevates the group's offering by introducing textile and technical materials into its product portfolio. This expansion fosters valuable synergies with leather goods and footwear, enabling the group to provide customers with a comprehensive and seamless service. The company's vertically integrated production structure facilitates swift responses to customer needs, offering significant flexibility in customisation, quantities, and lead times while ensuring full control over quality and traceability. Tessitura Oreste Mariani holds both Global Organic Textile Standard (GOTS) and Global Recycle Standard (GRS) certifications and is also a member of Better Cotton. Moreover, it adheres to the 4sustainability® Chemical Management Protocol, actively eliminating toxic and harmful substances from its production process in line with the ZDHC Manufacturing Restricted Substances List (MRSL).

Tessitura Oreste Mariani - Visit website